◆Pore size increase

Causes of occurrence: the design value of the cutter diameter is too large or the cutter edge has burrs; the cutting speed is too high; the feed is improper or the machining allowance is too large; the main cutting edge of the cutter is too large; the cutter is bent; the cutter edge adheres to the built-up chip; the cutter edge is out of tolerance during grinding; the cutting fluid is not suitable; the surface of the cutter shaft is not wiped clean of oil or the cone surface is knocked during installation of the cutter; the flat tail of the cutter shaft is out of position after being inserted into the main shaft of the machine tool, and the cone interferes; the main shaft is bent or the main shaft bearing is too loose or damaged; the cutter floats unflexible; the cutter is not concentric with the workpiece and the two hands are not evenly force when hand-tapping, which makes the cutter sway left and right.

Remedies: Reduce the outer diameter of the die according to the specific situation; reduce the cutting speed; adjust the feed or reduce the machining allowance appropriately; reduce the main cutting edge angle appropriately; straighten or scrap the bent and useless die; carefully grind it to the qualified one with oil stone; control the swing within the allowable range; select the cutting fluid with better cooling performance; before installing the die, the inside of the die cone and the machine tool spindle cone hole must be wiped clean of oil, and the konical surface that has been knocked is polished with oil stone; grind the flat tail of the die; adjust or replace the spindle bearings; readjust the floating chuck and adjust the coaxiality; pay attention to the correct operation.

◆Pore size reduction

Causes of occurrence: the design value of the cutter diameter is too small; the cutting speed is too low; the feed rate is too large; the main cutting edge of the cutter is too small; the cutting fluid is not suitable; the worn part of the cutter is not ground during grinding, and the elastic recovery makes the hole diameter smaller; when cutting steel parts, if the allowance is too large or the cutter is not sharp, it is easy to produce elastic recovery, which makes the hole diameter smaller and the hole round, and the hole diameter is not qualified.

Remedies: replace the cutter with a larger outside diameter; increase the cutting speed appropriately; decrease the feed rate appropriately; increase the primary relief angle appropriately; select a cutting fluid with good lubricity; replace the cutter regularly and grind the cutting part of the cutter correctly; when designing the size of the cutter, the above factors should be considered or the values should be determined according to the actual situation; perform experimental cutting, take an appropriate allowance, and grind the cutter sharply.

◆The position accuracy of the counterbored hole is out of tolerance

Causes: wear of the guide bush; the bottom of the guide bush is too far from the workpiece; the guide bush is short and inaccurate, and the spindle bearings are loose.

Remedies: Regularly replace the guide bushing; extend the guide bushing to improve the fit between the guide bushing and the reamer gap; timely repair the machine tool and adjust the main shaft bearing clearance.

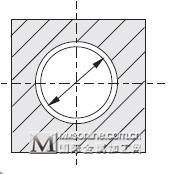

◆ Counter hole is not round

Causes of generation: the cutter is too long, rigid, and vibrates during reaming; the main cutting edge of the cutter is too small; the cutter edge is narrow; the allowance for reaming is too small; there are notches, cross holes on the inner hole surface; there are sand holes, gas holes on the hole surface; the main shaft bearing is loose, there is no guide bush, or the clearance between the cutter and the guide bush is too large, and the workpiece deforms after clamping due to the thin wall of the workpiece.

Remedies: For hammers with insufficient rigidity, an uneven tooth pitch hammer can be used, and the installation of the hammer should adopt a rigid connection, increasing the main cutting edge; select a qualified hammer, control the position tolerance of the pre-machined process hole; use an uneven tooth pitch hammer, use a longer and more precise guide bush; select a qualified blank; when using an equal tooth pitch hammer to machine a more precise hole, the machine tool spindle clearance should be adjusted, and the clearance of the guide bush should be required to be higher or use appropriate clamping methods to reduce the clamping force.

◆The life of the milling cutter is low

Causes: inappropriate material for the die; the die was burned during grinding; inappropriate cutting fluid, the cutting fluid did not flow smoothly, and the surface roughness value of the machined cutting edge after grinding was too high.

Remedies: Select the material of the tap according to the material to be processed, hard alloy tap or coated tap can be used; strictly control the cutting amount during grinding to avoid burning; often select the cutting fluid correctly according to the material to be processed; often clear the chips in the chip removal groove, use sufficient pressure of cutting fluid, and grind or grinding to the required accuracy.

◆High surface roughness value of the inner hole

Causes of occurrence: excessive cutting speed; inappropriate cutting fluid selection; large main cutting edge angle of the reamer, the cutting edges are not on the same circle; excessive allowance for hole machining; uneven or too small allowance for hole machining, local surface not machined; cutting part of the reamer is out of tolerance, cutting edges are not sharp, surface roughness; too wide cutting edge of the machined hole; poor chip removal during hole machining; excessive wear of the reamer; damage to the reamer, burrs or chipping of the cutting edges; built-up chips on the cutting edges; not suitable for zero degree positive cutting edge or negative cutting edge reamer due to material reasons.

Remedies: reduce cutting speed; select cutting fluid according to the workpiece material; properly reduce the main cutting edge angle, and correctly grind the cutting edge of the reamer; properly reduce the allowance of the hole to be铰ed; improve the position accuracy and quality of the bottom hole before ing or increase the allowance of the hole to beed; select qualified reamer; grind the width of the cutting band; reduce the number of teeth of the reamer according to the specific situation, increase the space of the chip flute or use a reamer with a negative cutting edge angle to facilitate chip removal; replace the reamer regularly, and grind the grinding area when grinding; the reamer should be protected during grinding, use and transportation to avoid damage; for the damaged reamer, it should be repaired with a fine oil stone, or replaced; use an oil stone to grind to qualified, and use a reamer with a front angle of 5° ~ 10°.

◆The inner surface of the hole has a distinct the tuna

Causes: too large allowance for counterboring; too large clearance angle of the cutting part of the counterbore; too wide cutting belt; surface of the workpiece has blowholes, sand holes and too large journal swing.

Remedies: reduce the allowance of the hinge hole; reduce the back angle of the cutting part; grind the width of the cutting edge; select qualified blank; adjust the main shaft of the machine tool.

◆Chisel tooth breakage

Causes: too large allowance for drilling; too high hardness of workpiece material; too large play of cutting edge, uneven cutting load; too small principal included angle of the reamer, which increases the cutting width; when drilling deep holes or blind holes, too much chips, not removed in time and the tooth is already ground when grinding.

Correction measures modify the preprocessed hole diameter size; reduce the material hardness or change to a negative anterior angle hinge or hard alloy hinge; control the swing difference within the qualified range; increase the main cutting edge; pay attention to the timely removal of chips or use a blade with a cutting edge; pay attention to the quality of grinding.

◆Chisel broken

Causes: too large allowance for reaming; improper distribution of allowance and selection of cutting data for reaming conical holes; small chip space of reamer cutter, chip jamming.

Remedial measures: modify the preprocessed hole diameter; modify the allowance distribution, and select the cutting data reasonably; reduce the number of cutting teeth of the tap, increase the chip space, or grind off one tooth of the cutting tooth.

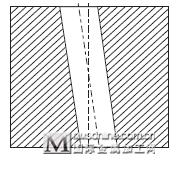

◆The center line of the hole after drilling is not straight

Causes of generation: The deviation of drilling before reaming, especially when the hole diameter is small, the rigidity of the reamer is poor and cannot correct the original bending; the main cutting edge of the reamer is too large; poor guidance, which makes the reamer easy to deviate from the direction during reaming; the cutting part is too ; the reamer moves back and forth at the gap in the middle of the hole; when reaming by hand, too much force is applied in one direction, which forces the reamer to deviate to one end, destroying the perpendicularity of the reamed hole.

Remedies: correct the hole by increasing the drilling or boring operation; reduce the main cutting angle; adjust the appropriate reamer; exchange the reamer with a guide part or a longer cutting part; pay attention to the correct operation.