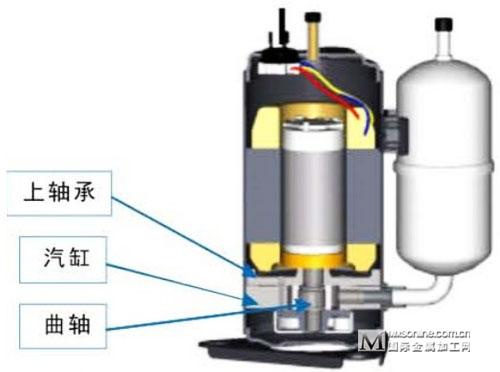

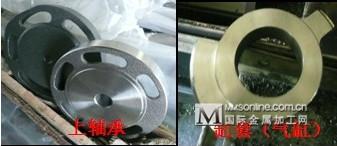

The main components of the air conditioning compressor core include the cylinder, frame, cylinder head, crankshaft, slide plate, piston, etc. Among these components, the cylinder, cylinder head, and frame are often made of gray cast iron (HT250), while the piston is made of nickel-chromium-molybdenum cast iron and the crankshaft is made of ductile cast iron QT500-7.

The CBN blade model for processing gray cast iron materials is BN-S30, which has a high hardness, good impact resistance, good toughness, and good wear resistance. It is suitable for the field of cast iron cutting processing and can be used for both rough and finish machining. The BN-K20 model is developed by Huarong for precision machining of cast iron. The CBN particle size is smaller and the CBN content is higher, which is suitable for high-speed precision machining. When machining piston parts with nickel-chromium-molybdenum alloy cast iron, the single-sided machining amount (cutting depth) is less than 2.5mm, and the BN-S30 model blade can also be used for high-speed cutting processing of nickel-chromium-molybdenum cast iron. If the single-sided cutting amount is greater than 2.5mm, the BN-K1 model blade is used for rough turning of nickel-chromium-molybdenum alloy cast iron to improve machining efficiency and reduce production costs. The hardness of the CBN blade model for machining cast iron is BN-K20, BN-S30, BN-K1 in order; and the toughness is from high to low BN-K1, BN-S30, BN-K20, BN-K10 model.

Comparison of cutting parameters commonly used for machining gray cast iron parts such as cylinders, cylinder heads, and frames for air conditioning compressors on CNC lathes:

Zhuzhou Diamond YBD, Mitsubishi Japan UC5115 and Kyocera CA4515 are all the material brands of hard alloy coated cutting tools (CNC cutting tools); the cutting line speed is generally 200--350m/min, and the cutting speed of BN-S30 grade of non-metallic bonding cubic boron nitride cutting tool is: 300-650m/min for roughing gray cast iron cylinder, cylinder head, frame; 350-750m/min for finishing gray cast iron cylinder, cylinder head, frame.

When machining gray cast iron cylinder, cylinder head and frame by CNC lathe, three kinds of hard alloy coated CNC tools are all sensitive to cutting linear velocity, the higher the linear velocity, the lower the tool life, and the upper limit of linear velocity is 330m/min. However, the non-metallic binder CBN of BN-S30 grade is not sensitive to cutting linear velocity, and users can choose according to their own equipment and processing conditions of gray cast iron. In principle, considering the out-of-roundness of cylinder, cylinder head and frame blank, the low linear velocity of 100-350m/min is often used for rough machining of gray cast iron; when the dynamic balance of cylinder, cylinder head and frame after machining gray cast iron is good, the cutting speed above 600m/min can be used, and the surface quality of the machined parts is excellent.

New cubic boron nitride tools BN-S30 and BN-K20 are developed for grey cast iron processing, mainly used for grey cast iron mechanical processing in the automotive industry, such as turning grey cast iron brake discs, cylinders, cylinder heads, frames, automotive flywheels, clutch pressure plates, compressor cylinder sleeves, automotive cylinder sleeves, engine cylinder blocks, cylinder heads, transmission cases, etc., made of grey cast iron and ductile iron.

New type of super hard BNS30 grade CBN tool, using non-metallic bonding agent, greatly improves the life of the tool when machining gray cast iron gray iron parts. In addition, by using sharp edge treatment, better surface roughness can be obtained, and the problem of tearing at the edge and stop of the tool when cutting gray cast iron workpieces can be solved. When precisely turning the braking surface of the cast iron brake disc, the roughness can be within Ra1.6. Suitable for high-speed cutting of gray cast iron, high-strength ductile cast iron such as HT250, HT200, HT300; QT500, QT600, QT700, QT800, QT900 and isothermal quenched ductile cast iron (ADI).

CBN ultra cutting tools are suitable for rolling mill, water pump, wind power, compressor, bearing, gear, automotive transmission system, engine system, brake disc and other mechanical processing fields.