Turbochargers can effectively enhance automotive engine power and dynamic performance while reducing fuel consumption, offering dual advantages of energy efficiency and environmental protection. Gasoline engine turbine housings are predominantly cast from austenitic heat-resistant stainless steels such as grades 1.4848, 1.4837, and 1.4826. While these materials exhibit high tensile strength, they present challenges such as significant elasticity and susceptibility to deformation during machining. Additionally, the irregular shape of turbine housings further exacerbates the demanding nature of the machining conditions.

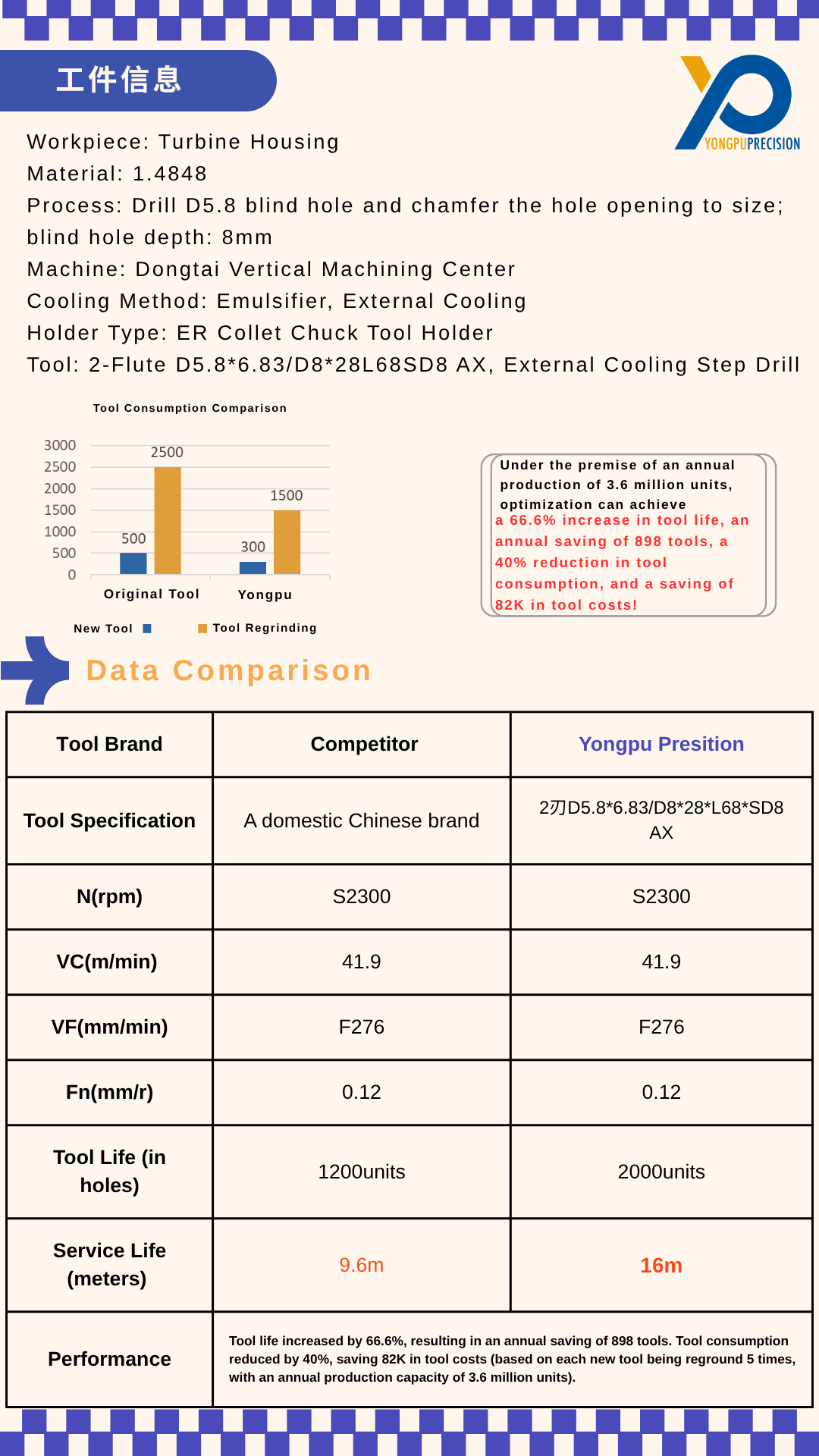

In the drilling processes of high-temperature alloys and heat-resistant stainless steel turbine housings, the industry commonly faces the following core challenges:

Poor thermal conductivity of materials, leading to hardening phenomena on machined surfaces;

Difficulties in chip breaking and inefficient chip evacuation, directly impairing cooling effectiveness;

Insufficient wear resistance of tools, failing to meet high-load machining requirements;

Irregular part geometries, often requiring rough casting positioning, resulting in poor fixture stability.

Addressing these machining pain points, Yongpu Precision has developed specialized drill bits for turbine housings, providing targeted solutions with the following core technical features:

Wide flute design to increase chip pocket space, significantly enhancing chip evacuation efficiency;

Customized specialized coatings to effectively improve tool wear resistance and extend service life;

Small helix angle structure to enhance tool rigidity and reduce deformation during cutting;

Sharp edge technology to ensure smooth and stable cutting forces, mitigating machining deviations and tool breakage risks caused by insufficient fixture stability.

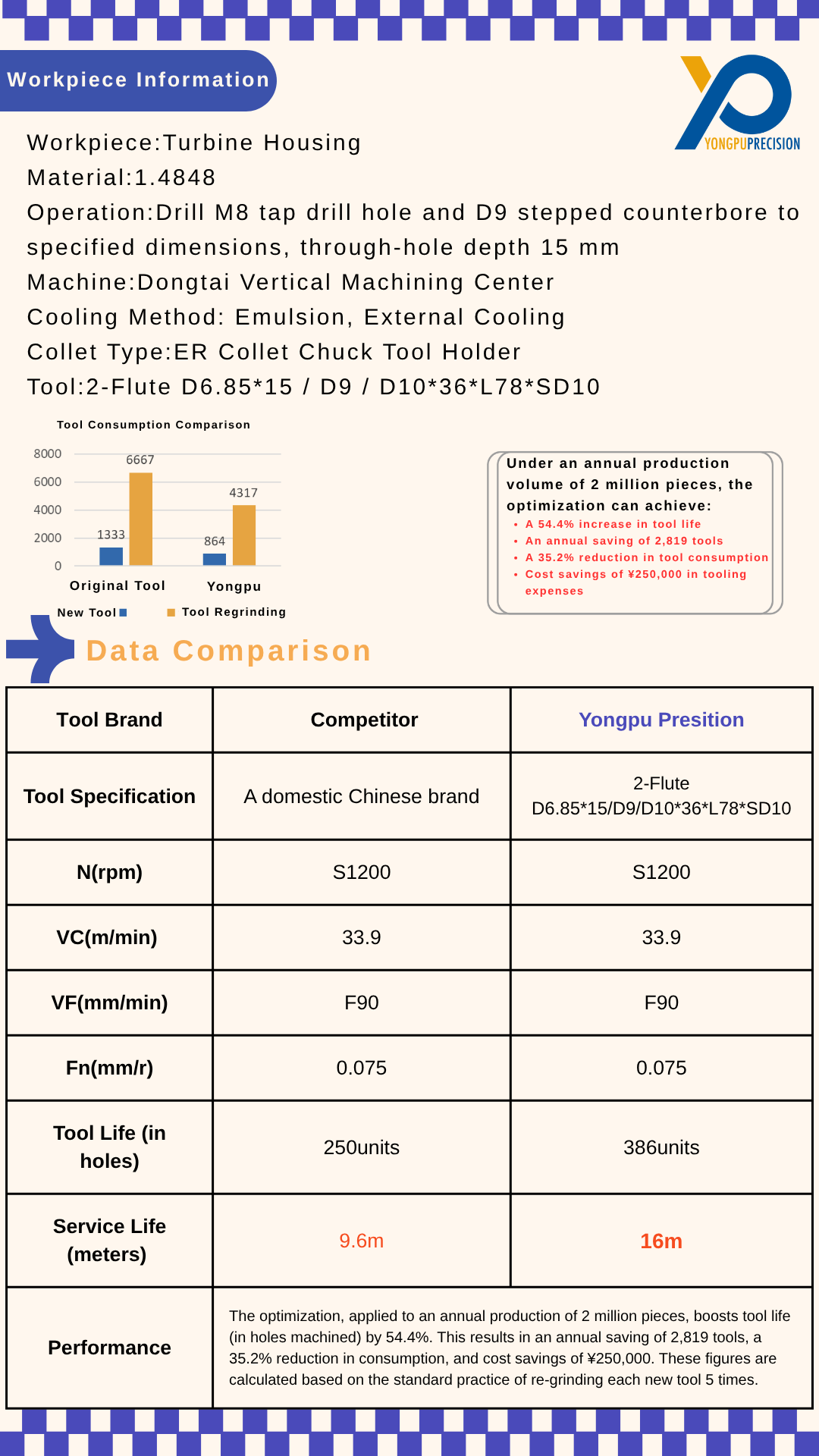

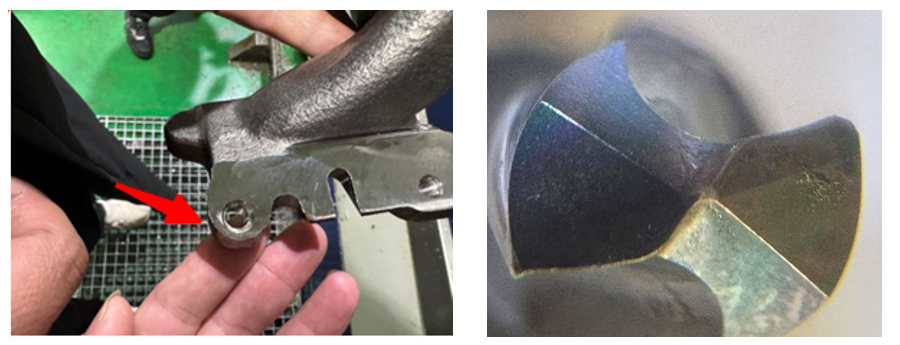

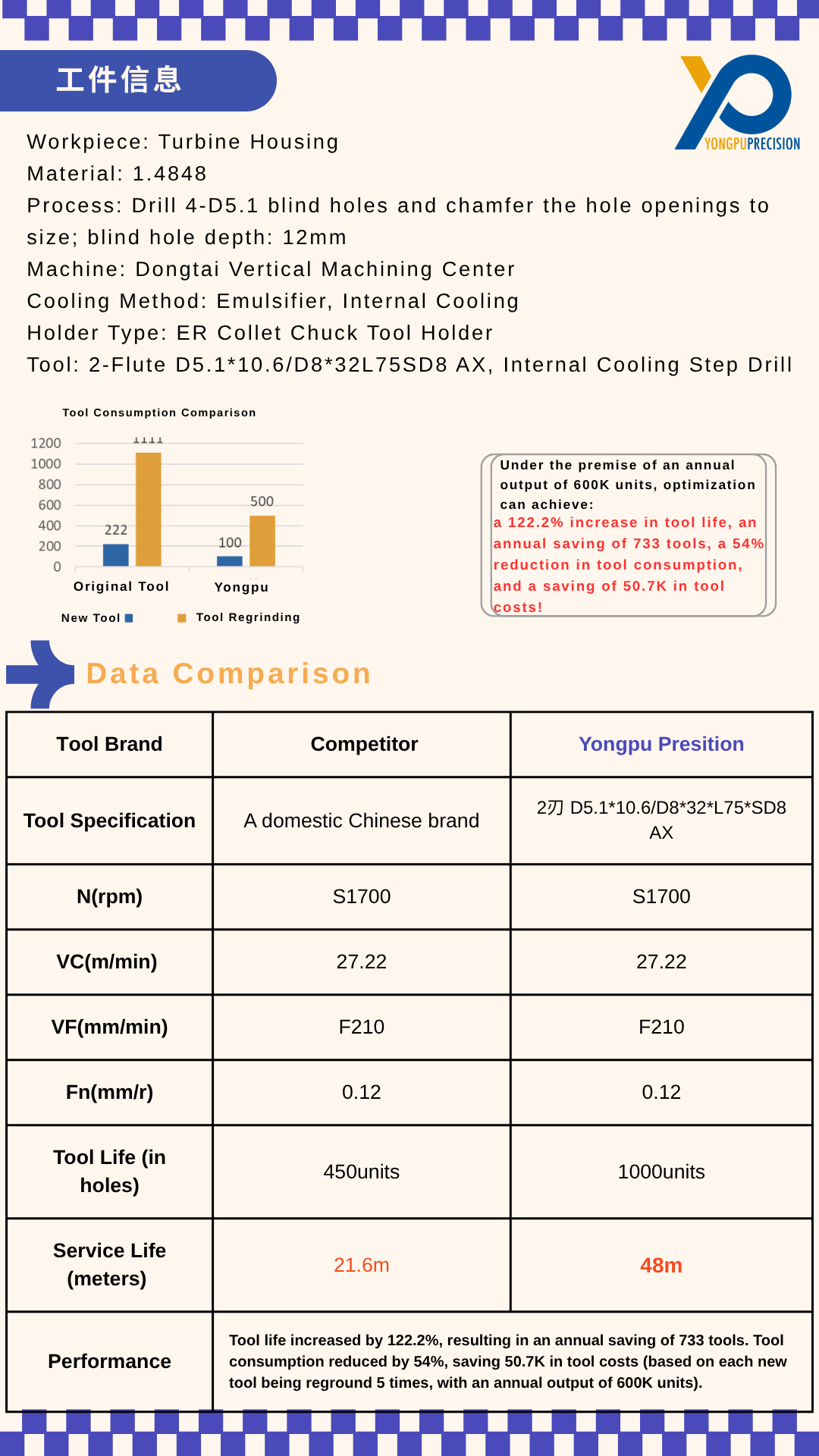

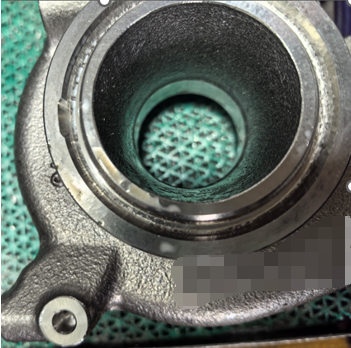

Application Case

https://mw.jgvogel.cn/magazine/

Tools World:

https://www.mcimt.com/e/25/9.html

Metal Processing: