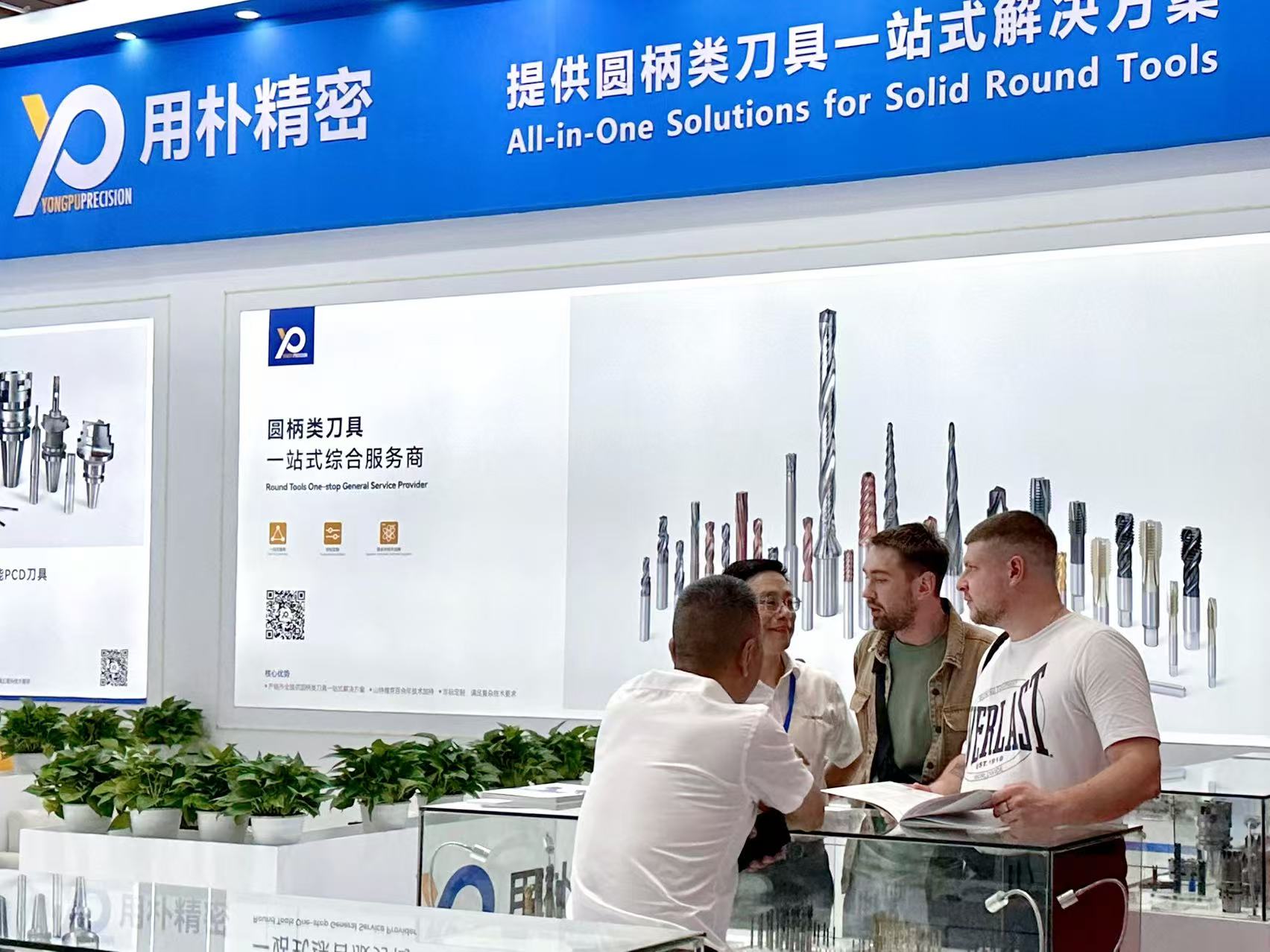

From November 5th to 8th, 2025, the Shenzhen World Exhibition & Convention Center hosted the highly anticipated 2025 DMP Greater Bay Area Industrial Expo. As one of the largest and most influential industrial events in South China, this year's exhibition attracted numerous renowned enterprises from around the globe, showcasing cutting-edge technologies and innovative products in the industry. Suzhou Yongpu Precision Technology Co., Ltd. made a remarkable appearance at this exhibition, drawing extensive attention with its series of high-performance cutting tool products.

Suzhou Yongpu Precision Technology Co., Ltd. is a high-tech enterprise specializing in the production of precision cutting tools and cutting technical services. It is dedicated to the research, development, and production of carbide rods, precision tools, and precision coatings. Its products are widely used in precision manufacturing industries such as automotive, aerospace, military, molds, and refrigeration. With the mission of providing innovative round-shank tool solutions to help customers improve efficiency and reduce costs, the company boasts a professional R&D team, has established a comprehensive precision tool manufacturing industry chain, and has passed the ISO9001 quality certification system certified by Germany's TUV. For this exhibition, Suzhou Yongpu Precision Technology dispatched a professional team composed of elite members to provide expert and attentive service to visiting clients.

At this exhibition, Suzhou Yongpu Precision Technology highlighted its most competitive new products in the YPP Drill® series, YPP Mill® series, YPP Tap® series of various taps, and PCD tools, especially the complete PCD tool solutions for aluminum alloy cylinder blocks and heads. These products attracted a large number of visitors who stopped to inquire, thanks to their outstanding performance and innovative design.

Taking the new YPP Drill® series products as an example, the BS200U Drill is a high-performance tool for efficient hole machining in steel, cast iron, and stainless steel materials. Its diameter range is Φ3.00 – Φ16.00 mm, and it possesses a series of prominent features. In terms of chip evacuation performance, a more open flute space combined with a back-tapered core design not only strengthens the drill point but also significantly improves rear-end chip evacuation. The straight cutting edge enhances edge strength, ensuring tool stability during machining. The waveform chisel edge design provides excellent centering capability and machining accuracy, allowing precise positioning of drill holes. The S-shaped chisel edge modification enhances chip curling ability, improves chip breaking performance, and effectively avoids chip winding issues during processing.

The YMD20PR Drill, a burr-suppression drill, provides an effective solution for suppressing exit burrs in drilling operations. It can suppress the generation of exit burrs and caps on workpieces, with a diameter range also of Φ3.00 – Φ16.00 mm. The wide flute and large rake angle design help prevent chip clogging and improve cutting sharpness, making the machining process smoother. The special chisel edge design offers excellent centering capability, reducing the impact of runout on burrs at the exit. The crescent-shaped cutting edge optimizes chip curling and breaking performance, ensuring smooth chip evacuation during processing.

The RD200U Drill is a drill-reamer tool that combines drilling and reaming functions, enabling efficient hole machining that integrates drilling and reaming, thereby saving tool magazine positions and machining time. It possesses high-precision hole machining capability, with hole machining accuracy ≥ IT7. This product has 2 drilling cutting edges that first complete solid hole drilling, with a drill diameter 0.05 - 0.08mm smaller than the reamed diameter. The 4 axially offset reaming cutting edges then finish the final hole machining and are responsible for the required reamed surface quality, dimensional accuracy, and roundness. The special chisel edge design provides excellent centering capability, improving hole machining accuracy, and the straight cutting edge also enhances edge strength.

The DS50H Drill, a mold drill, is designed for efficient machining of high-hardness materials (~HRC50), with a diameter range of Φ3.00 – Φ16.00 mm. Its low helix angle design enhances tool rigidity, allowing it to better handle the challenges of machining high-hardness materials. The straight cutting edge increases edge strength, ensuring tool durability during machining. The tool tip R-angle protection strengthens the tip strength, reducing the risk of tip damage during processing. The substrate suitable for mold processing enhances tool wear resistance, delays tool wear, and significantly extends tool service life, giving it distinct advantages in the mold processing field.

Furthermore, other products such as the QMD20U MODULAR Drill (modular indexable insert drill), SFP Drill (universal drill), LFRA deep hole drill, and LSRA deep hole drill also have their own characteristics, meeting the diverse needs of different customers. The products displayed in the areas of milling cutters, taps, and PCD tools also performed exceptionally well. For instance, its complete PCD tool solution for aluminum alloy cylinder blocks and heads attracted the attention of many automotive manufacturing-related enterprises due to its advantages such as high wear resistance, mirror-like finishing effects, lightweight tool body design, and cost reduction through replaceable cartridges.

During the exhibition, Suzhou Yongpu Precision Technology's booth was consistently crowded with a continuous stream of visiting clients seeking consultations. Many clients spoke highly of the exhibited products, noting that they not only demonstrated excellent performance but were also designed with full consideration of various practical machining needs, offering high practical value by effectively improving production efficiency and reducing costs. Some clients expressed their intention for further cooperation on the spot.

The successful showcase of Suzhou Yongpu Precision Technology Co., Ltd. at the 2025 Shenzhen DMP exhibition not only demonstrated its technical strength and innovation capabilities in the field of precision cutting tools but also laid a solid foundation for further market expansion and strengthened customer cooperation. As the manufacturing industry's demand for precision tools continues to grow, Suzhou Yongpu Precision Technology is poised to exert greater influence within the industry and contribute more to the development of the precision manufacturing sector, leveraging its high-quality products and services.